Log Cabin FAQ’s

and Expert Advice

Beaver Log Cabins, the single best place for all your needs of log cabins needs.

frequently asked questionS

Below are some of the most frequently asked questions related to Beaver Log Cabins, our products, our services, our delivery and quality

Beaver Log Cabins main objective is to satisfy its customers need in the best possible way. For us, at Beaver Log Cabins we believe that nothing else is more important than customer satisfaction while buying top quality log cabin products at the best price.

At Beaver Log Cabins our customers are our main assets and therefore we care for each and every minor problem that you our customer may have. Our customer care executives are always ready to assist you in the best possible ways, our design team are always willing up help design your dream log cabin, our technician team is always ready to help you in any way they can.

For any sales related queries that you may have please email us at sales@beaverlogcabins.ie and for any other types of problems i.e. prices, queries, quotes, or any questions of your choice, you can directly get in touch with us via telephone on 074-9368972 (Donegal) 066- 7119936 (Kerry) or 019-022624 and 028-71277127 from Northern Ireland.

Beautiful Crafted Log Cabins

Bergen XL – Type 2 6.77m x 4.52m

€9,596.78Original price was: €9,596.78.€7,197.58Current price is: €7,197.58.Manchester Log Cabin 4.40m (+2.17m Veranda) x 5.90m

€16,043.81Original price was: €16,043.81.€12,032.86Current price is: €12,032.86.Log Cabin Blackpool 4.40m x 3.40m + 0.80m Overhang

€10,565.45Original price was: €10,565.45.€7,924.09Current price is: €7,924.09.Log Cabin Clockhouse F0514 14.60m x 4.00m

€48,067.13Original price was: €48,067.13.€36,050.35Current price is: €36,050.35.Clock House Drumahoe 15.00m x 4.04m

€42,226.55Original price was: €42,226.55.€31,669.91Current price is: €31,669.91.Log Cabin Cashel 16.00m x 4.00m MT Overhang

€64,257.52Original price was: €64,257.52.€48,193.14Current price is: €48,193.14.

FAQs

A. Only for cabins sized 25sq meters & over. See link for more details.

- The supply of the assembly services are made to our ROI customers by a ROI company.

- The supply of the flat pack log cabin is made by our UK company, thus a ROI customer must either collect the flat pack from your warehouse in Northern Ireland or arrange its own transport.

For further information or clarification please call us on: 074-9368972

A. We only use shingles.

A. Yes, foundations, assembly, electrical work & painting jobs are priced additionally.

A. Scandinavian pine & spruce timber.

A. By our joiners – 1-3 days depending on size

A. Yes, we have our own electricians and painters, who have worked for us for years, we never outsource work.

A. Yes, all of our products can be customised and you can even work with our design team to design your own log cabin.

A. This rarely happens, but still in this case you just need to contact us and we will place your missing/damaged items very soon without delay.

A. We suggest going with a thicker log (70mm) to ensure the cabin is kept warm all year through. Research has shown that log homes retain 40% more heat than block or brick.

A. Yes. We recommend applying 1 coat x 34 microns of paint every 2 years. This will help to keep your log cabin look new, and also protects the timber from further wear & tear.

A. The exterior paint you use on your log cabin is crucial to the protection and life-span of the

timber. Never use a cheap paint and always ensure that the appropriate paint for the job is used. For base coat we recommend only Sikkens Rubbol Primer Plus. For top coat we recommend only Sikkens Satura Plus. View full details.

A. No, here is the insurance company that we recommend to insure log cabins – http://www.brittoninsurance.ie

A. Yes! Contact us today with your measurements & we can help you.

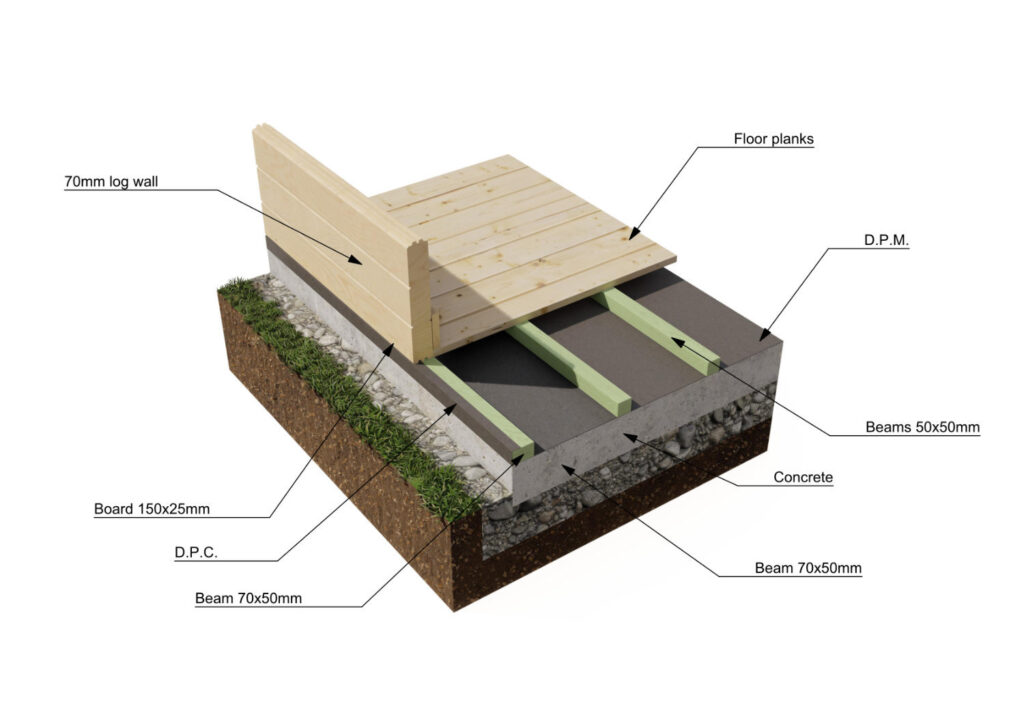

BASES & FOUNDATIONS

Foundation

A proper and sound foundation is a deciding factor for the safety and longevity of your cabin. Only level, properly squared-off foundations will be capable of taking the load of your cabin for a trouble-free installation.

Faulty foundations will definitely result in out-of-shape walls. Doors and Windows will be difficult to open and close.

The perimeter of the foundation should be no less than the perimeter of the outside walls of the cabin and ideally, should extend at least 5cms around the perimeter of the base of the cabin.

Step by step on a non-insulated base

- Cut the 3×2 Treated Timbers to the perimeter of the cabin. Place around the slab with the 2inch side up.

- Staple/ tack DPC underneath of the 3×2 treated timbers allowing 3inches to overhang outside.

- Screw the timbers together, ensuring there level and square.

- Fix the 3×2 Treated timber to the concrete with express nails or concrete screws (these are not supplied) Space them at 4-600mm apart.

- Turn the DPC plastic up and over on the outside. NOTE: At this stage, we would recommend building the cabin as floor joists can be done when the unit is watertight.

- Roll out DPM plastic

- Decide which way you want your flooring to run, fix the battens in the opposite direction with concrete screws or express nails(these are not supplied).

- Nail down your T&G flooring and skirt around the edges.

TIPS:

Spend time on your base timber ensuring it’s level and square, if not it will cause a lot of problems with the build otherwise.

Seal the joint between the DPC concrete & DPC and first log. This can be also be done by using a kicker and timber underneath (this kicker is not supplied please see the insulation base sketch)

Flooring gets dirty very quickly use covers/cardboard until varnish/stained.

Non-insulated base

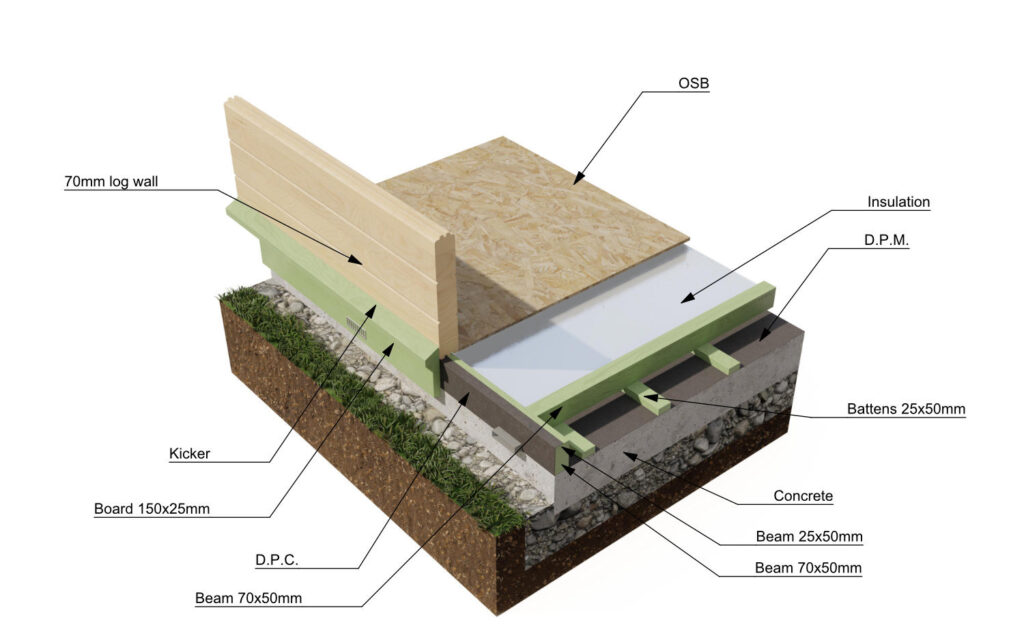

Insulated base

Step by step on an insulated base

- 3×2 Treated Timber on the edge around the perimeter of the unit with DPC underneath to form the base. Allow 105mm of the DPC to overhang the outside the base for now.

- Square and level the 3×2 Timber base then fix it down to the concrete using concrete fixers/screws (these are not included) space these roughly 4-600mm apart. NOTE: If the base is not correctly square and level it will have irreversible problems during build. TAKE YOUR TIME and have it right.

- Nail the 2×1 Treated Timbers on top of the 3×2 Treated Timbers.

- Roll out the DPM inside the base.

- Place the 2×1 Treated Timbers on the DPM plastic on right to left or back to front spaced 500mm apart. Make sure all 2 x 1 are 90mm back from 3×2 on the inside.

- Place the 3×2 Timbers into the base on the opposite direction of 2×1 treated timbers. These will be cut tight and fixed to your outside 3×2 with the 2×1 on top every 400mm .

- Once fixed down the DPC can be pulled up and over on the outside of the base. Drill out vent holes on the corners of the base , bigger cabins more vents on log sides. NOTE: At this stage it’s advisable to build the cabin as the following can be done after unit is watertight. It also means you can hide any wires required for sockets/switches.

- Insulation can be fitted in between the flooring joists.

- OSB can now be fitted.

- Finished flooring can now be fitted. If using timber click or PVC click underlay is to be used first.

OPTIONAL: kicker & 6×1 (not supplied)

The reason we say optional is because some people get creative at this stage. Basically what your trying to achieve is covering the joint between concrete and DPC and throwing/kicking the water from cabin wall away from base.

TIPS:

Use slate for packing base if low rather than timber.

Use a builders line to check for dips/humps in base.

Ensure concrete slab is higher than FGL so water can’t get underneath your DPM.

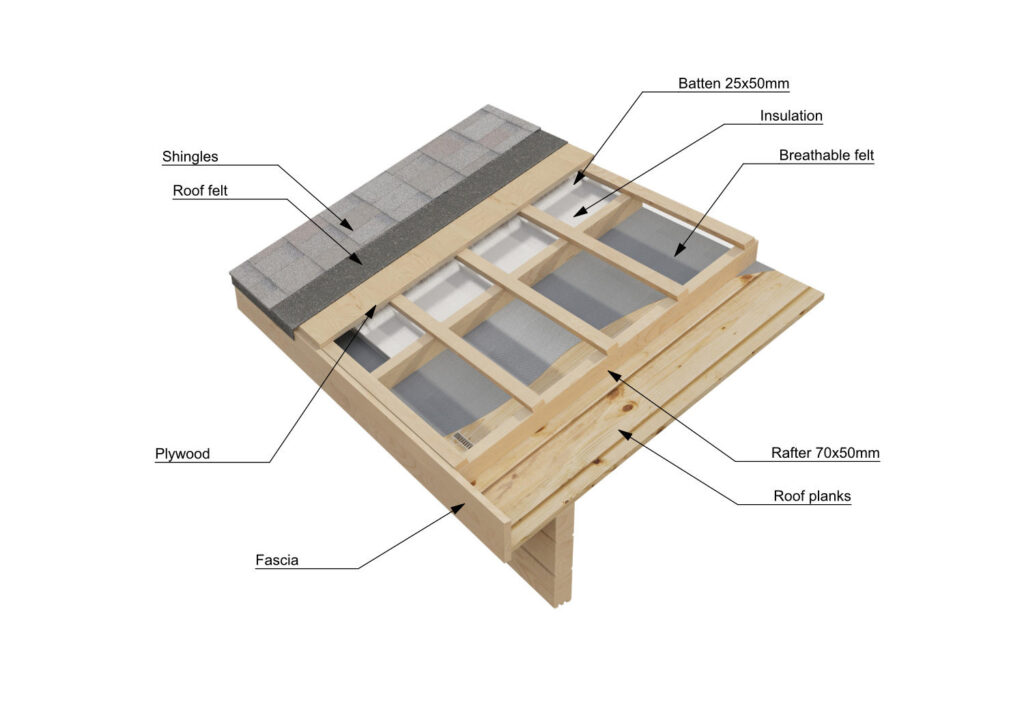

ROOFING

Step by Step on Insulating your roof

- Cut the T&G roofing boards plumb and straight across the roof.

- Staple/nail breathable felt on roof.

- Cut the 3×2 Timbers rafters spaced at 600mm centres across the roof. NOTE: Cut all 4 gable rafters with plumb cut top and bottom. Keep a plumb cut on the bottom and square at top for the rest , this gives you a channel to run wires before insulation.

- Cut four of the 6×1 Timbers with plumb cuts across the top and the bottom to be the exact size of your 3×2 rafters . Nail/screw flush with top of your 3×2 rafters.

- Fit the 7×1 facia boards , up stand on the facia will be in line with the 2×1 + plywood to the outside corner of facia (see pic)

- Fit your insulation in between the rafters, keep the insulation 150mm back from facia and gable rafters. This void can now have vent holes drilled, (4 low and 4 high )

- Nail the 2×1 timbers tight to the back of facia board , from this space your lats are every 300mm running up the roof cutting them off flush with 6x1s on the gables. NOTE: If your roof is over 2.4 place the lats on the work centre of the joining sheets.

- Cover the roof with the plywood .

- Cover the roof with the mineral felt allowing it to overhang by 50mm.

- Shingle and ridge cap roof.

- After painting/treating barges fit down on top of shingles

TIPS:

*Cutting T&G , measure up 1.5 inches from the bottom of the T&G , chalk a line, tack a timber on the line and use as a runner for your circular saw.

*make a guide for your facia by cutting two of the 2x1s at 5inchs and one at 7inches hold all 3 flush at one end and screw together. Then simply hold on rafter and bring facia up to hit underneath of 7inches of the 2×1

*mineral felt , on the 4 corners of the roof measure up 950mm from the facia , chalk/pull line keep the top of your felt to the line .

*shingles , first row is a double row. Put the top edge of the shingle down in line with your felt , take this row across the roof . Come back to where you stated but this Time start with half a shingle with the hex edges following the line of the first shingle and felt. 4 x nails per shingle, blob of glue over each nail

*ridges are created from the flats (rectangular) shingles. Each rectangular shingle is cut into 3 ridges buy continuing factory made cut. Fold over ridge and lap 30mm over dotted line on shingle.

Insulated Roof